Rifey-Udar-SD

6 672 000 RUB

Output per shift |

2720*pcs.

224*m2

575*pcs.

* Upon condition of continuous work of a vibrating press within 8 hours.

Equipment meets the requirements of Technical Regulation of the Customs Union

Declaration identification number

TC № RU Д-RU.АЛ16.В.29091

TC № RU Д-RU.АЛ16.В.29088

Date of declaration: 24.01.2014

Content:

- Aggregate bin DZ-10, two batchers по 5 metre cube. each

- Weighting batch-system with strain gauge

- Band conveyor L-7,4 m. with reducing batcher

- Batcher unit (Concrete and water batcher with strain gauge), on a frame

- Big-bag debagger or cement silo (advanced option)

- Warm conveyor KW-6 (L-6 м)

- Concrete mixer SG-750, V-0.7 m3

- Band conveyor L-7,4 m

- Vibrating press «Rifey-Udar»

- Control panel CMP in automatic mode

- Pneumatic equipment

- Punch-matrix

Description

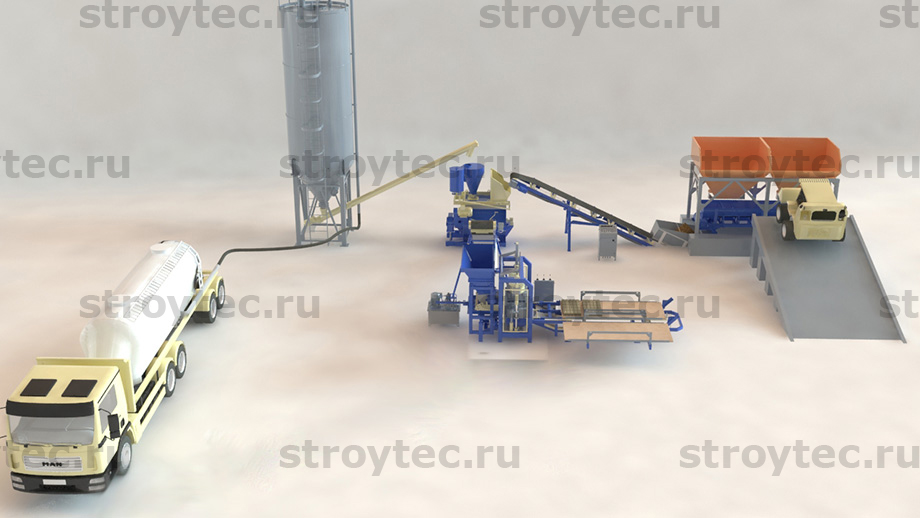

Processing unit «Rifey-Udar-SD» in basic configuration

- Aggregate bin DZ-15, two batchers 7,5 m3. each.

1А. Weighting batch-system with strain gauge. - Band conveyor L-7,4 м. with reducing batcher.

- Batcher unit (cement and water batchers), on a frame.

- Screw conveyor KW-6 (L-6 м.)

- Concrete mixer SG-750, V-0.7 m3.

- Band conveyor L-5 m.

- Vibrating press «Rifey-Udar» with punch-matrix 101.6.

- Control panel SD in automatic mode.

- Pneumatic equipment.

Productivity of the «Rifey-Udar-SD»

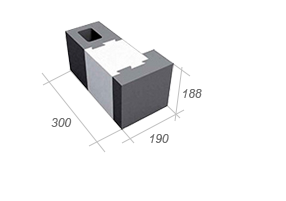

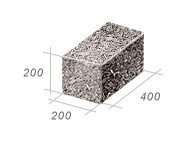

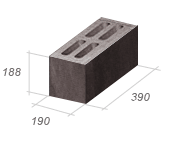

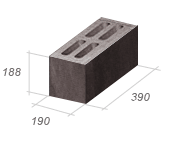

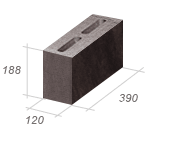

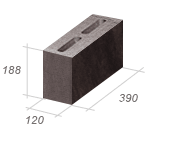

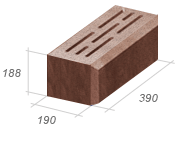

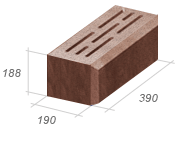

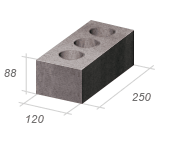

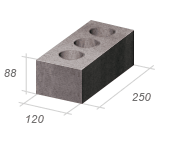

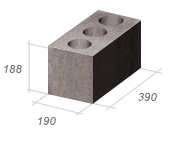

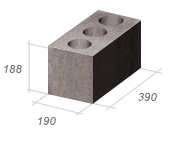

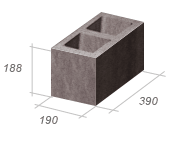

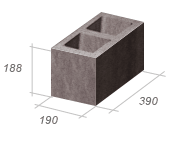

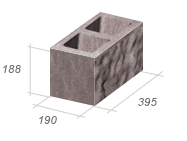

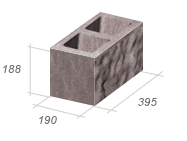

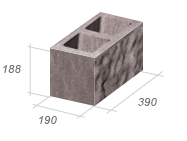

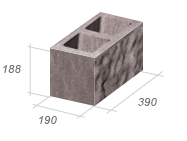

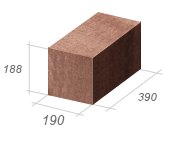

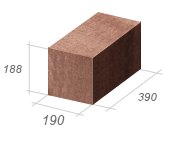

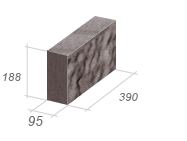

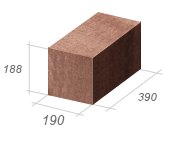

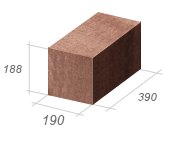

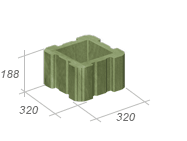

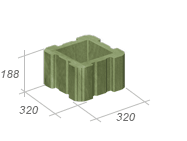

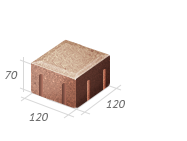

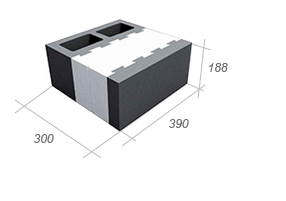

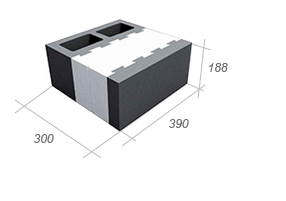

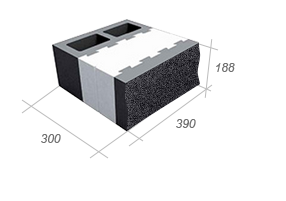

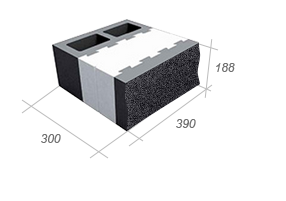

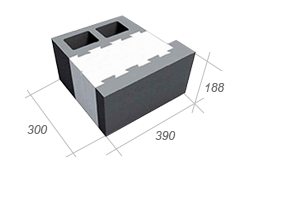

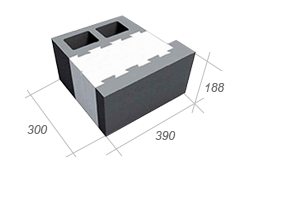

| Hollow wall stone 390*190*188 мм | — | 2720 pcs. per shift; |

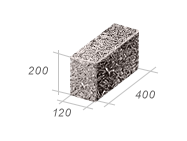

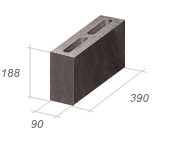

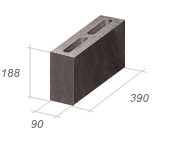

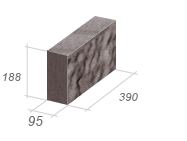

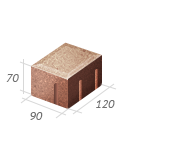

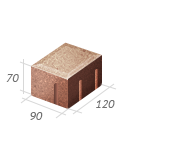

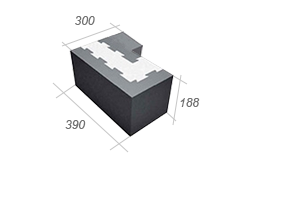

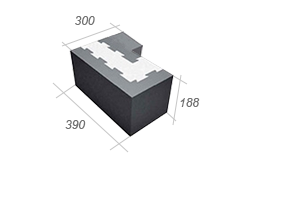

| Partition block 390*90*188 mm | — | 5440 pcs. per shift; |

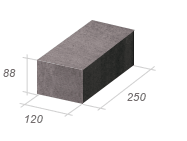

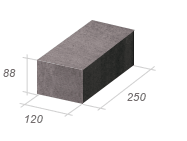

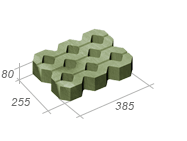

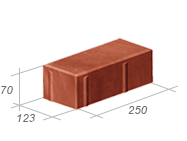

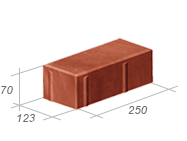

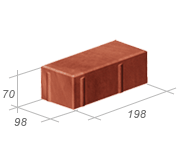

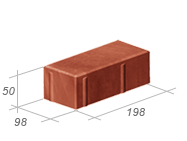

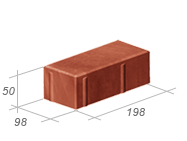

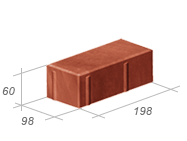

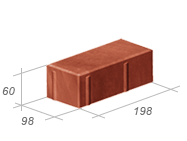

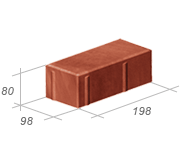

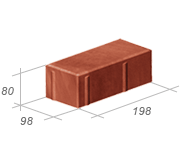

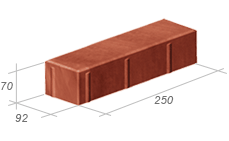

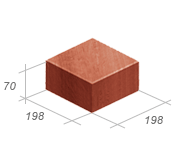

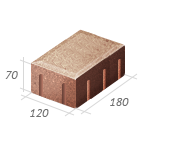

| Paving slab «Right angled» 200*100 mm | — | 224 sq. m per shift; |

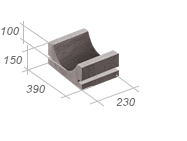

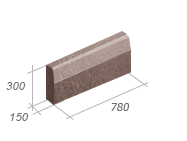

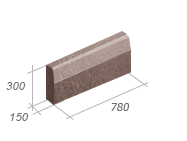

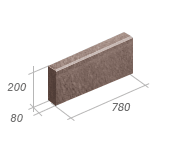

| Curb stone BK-4, 780*150*300 mm | — | 575 pcs. per shift; |

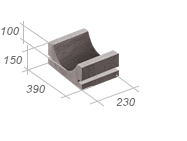

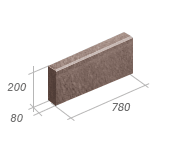

| Curb stone BK-5, 780*80*200 mm | — | 2300 pcs. per shift; |

Technical data of the «Rifey-Udar-SD»

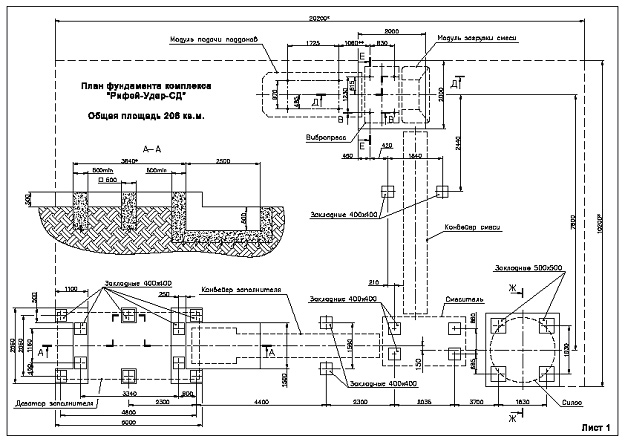

| Lenght, mm | — | 20200 |

| Width, mm | — | 10200 |

| Height, mm (excluding cement silo) | — | 3450 |

| Weight, kg | — | 11000 |

| Energy consuption | ||

| Voltage | — | 380 V; |

| Frequency | — | 50 Hz; |

| Power consuption | — | 46,4 kW; |

| Operating personnel | — | 3–4 persons; |

| Moulding area of vibrating press | — | 790*390 mm. |

| Height of moulded products | — | 50–230 mm.; |

| Moulding cycle | — | 36–50 sec.; |

Foundation plant

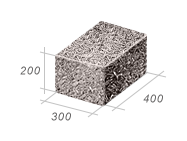

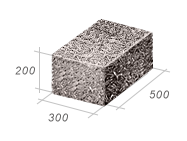

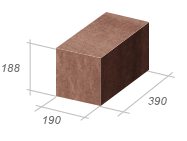

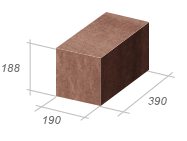

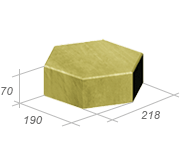

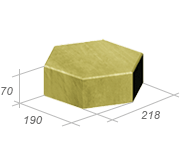

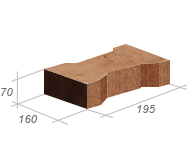

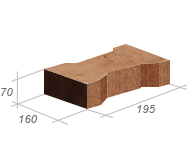

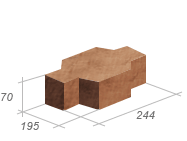

Types of products

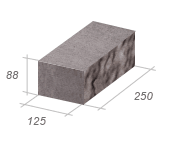

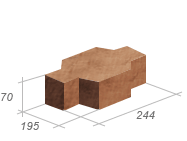

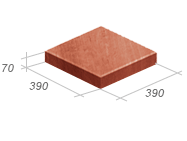

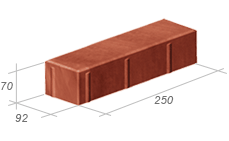

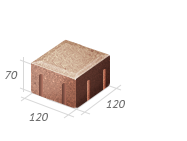

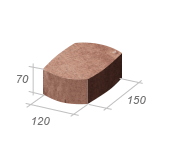

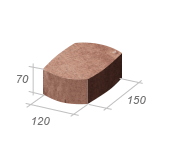

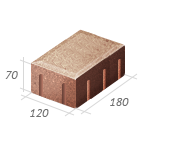

101.6

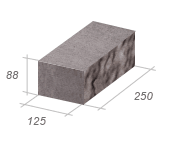

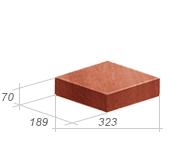

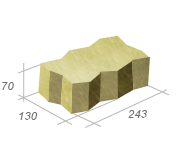

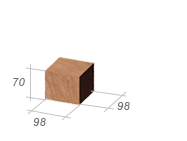

102.6

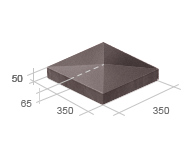

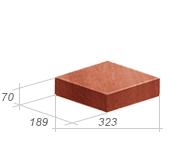

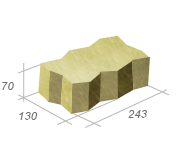

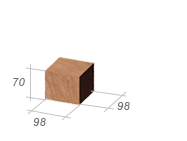

108.6

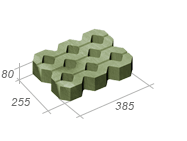

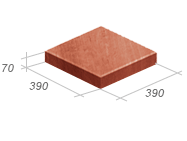

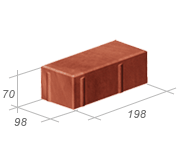

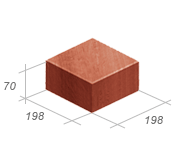

109.6

110.6

130.6

145.6

151.6

158.6

171.6

172.6

197.6

197.6

197.6

112.6

439.6

605.6

622.6

401.6

402.6

403.6

405.6

407.6

408.6

419.6

430.6

430.6А

430.6Б

430.6В

449.6

459.6

460.6

491.6Б

491.6В

491.6Г

491.6Д

614.6

616.6

701.6

701.6Б

702.6

703.6

704.6