Vibrating press «Rifey-Polus»

Output per shift |

Equipment meets the requirements of Technical Regulation of the Customs Union

Declaration identification number

TC № RU Д-RU.АЛ16.В.29091

Date of declaration: 24.01.2014

Content:

- Concrete mixer

- Component batcher

- High-angle conveyor

- Pump unit

- Vibrating press

- Control panel

- Rack, 2 pcs

- Pallet supply system

- Punch-matrix

Description

Manufacturing and trading of "Rifey-Polus" line by the "Stroytechnika" factory. Open your own business with Rifey vibrocompressing lines.

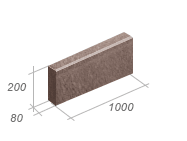

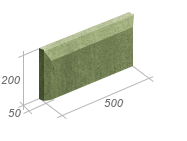

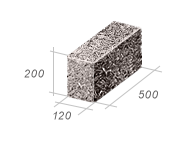

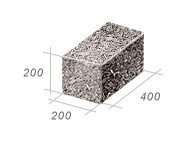

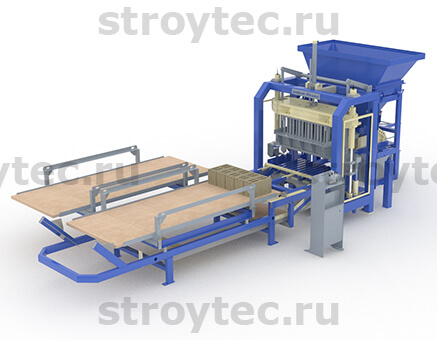

Purpose of the «Rifey Polus» line

The manufacturing line "Rifey-Polyus" is intended for production of wall stones, paving slabs, border (curb) stones, decorative and facing stones, park amenities by the vibrocompressing method from rigid concrete mixes.The Rifey-Polyus line is built by the modular principle, it means that the module of the line can independently operate, loading of the concrete mixes in a matrix is made by subsidiary means, pulling-out of pallets with ready products is made manually, but, of course, productivity decreases. The mix- and pallet supplying modules can be added to the module of a vibrating press at any time relatively easy and without additional works. The module of the batcher, a concrete mixer and the conveyor can be not used at all if there is a ready complex for a mix preparation (for example, at concrete goods plants).

Work of the line. For preparation of concrete mix it is giving a filler, cement and water to the weight batcher of a concrete mixer. The necessary amount of filler and cement in the batcher is provided with the operator visually according to the indexes of level which are available on the batcher. At achievement of the set level the operator stops providing of these components. Water level is provided automatically by means of the float-operated mechanism of the batcher. Giving of components from the batcher in the concrete mixer is carried out by the operator by turn of the handles opening a batcher bottom. After hashing of components the operator opens the hatch at the bottom of a concrete mixer, and ready mix moves on the conveyor which brings it in the loading bunker module. Mix preparation process periodically repeats for maintenance of necessary amount of mix in the vibrating press bunker. Turning on of electric motors of the mixer and the conveyor is made from the mixer and conveyor control panel. From the loading module bunker mix comes to a loading box, which delivers it in an area of vibropressing matrix and is loaded into it due to the vibration created by a vibrating table. After loading of a matrix to its top level, mix is condensed by means of a vibrating table and a punch. Ready stones are squeezed out from a matrix on the pallet and the trolley of the pallet-giving module moves on a rack. The rack established on the pallet-giving module is loaded by pallets with finished products and, after its full load, is removed with the help of traverses. Then the following rack is established with empty pallets and the cycle is repeated. The rack after filling moves in the steaming chamber or on a warehouse for a maturing of products.

Distinctive features of the line Rifey. Moulding of stones, as well as on all other lines of the "Rifey" series, is made on pallets, however on the "Rifey-Polus" line pallets from 8 to 40 mm thick can be used, thus the vibrating press doesn't demand any additional change-over. It is necessary to notice that quality of the let-out products depends on quality of pallets and developers recommend to use the plywood or wooden pallets 40 mm thick which are pulled together with metal hairpins. Other distinctive feature is simplicity and speed of replacement of form-building equipment. It is enough to turn off 10 bolts and the load-lifting mechanism to take a matrix and a punch through the top, free zone of a vibrating press. If the replaced matrix has other height, it is necessary, by means of jacks to lift or lower the loading module. This, rather simple operation, doesn't take a lot of time. Other reorganizations it isn't required.

One more feature of the "Rifey-Polus" line is that when unloading ready stones pallets from a rack aren't removed (only products are removed), thus during all cycle the man’s hand doesn't touch pallets.

Completing variants

Vibrating press «Rifey-Polus»

Output per shift

Technical Details:

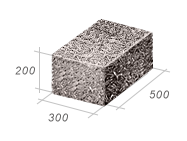

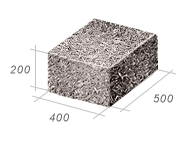

| Formed products area, mm | 1000 х 500 |

| Formed products height, mm | 50-250 |

| Total capacity, kW | 16,0 |

| Dimensions of the line (LxWxH), mm | 7500 × 2000 × 2800 |

| Weight, tonn | 5,5 |

Complex «Rifey-Polus»

Output per shift

Technical Details:

| Formed products area, mm | 500×1000 |

| Formed products height, mm | 50–250 |

| Total capacity, kW | 33 |

| Dimensions of the line (LxWxH), mm | 7400 × 8400 × 3000 |

| Weight, tonn | 7,5 |

Characteristics

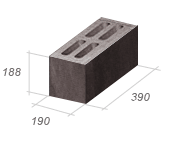

| Productivity*: | Formed products area | 500x1000 mm | ||

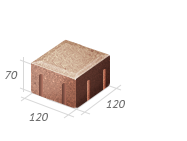

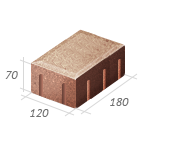

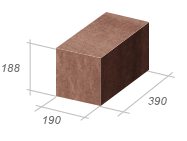

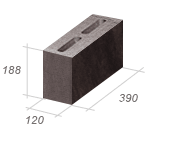

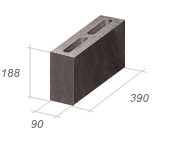

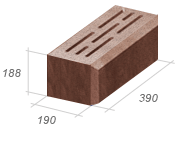

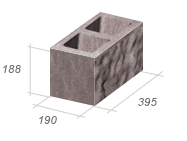

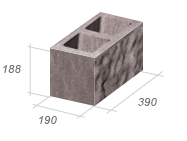

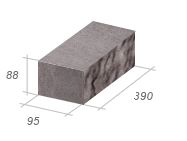

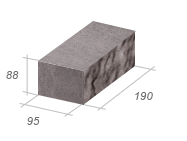

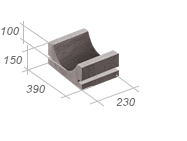

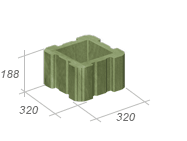

| Hollow stone 390х190х188 mm | 425 pcs./hour | Formed products height | 50–250 mm | |

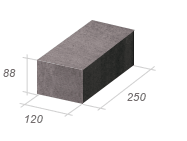

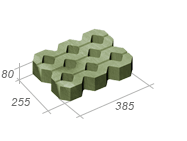

| Paving slab 200х100 mm sq. m | 50 кв. sq. m/hour | Moulding pallet dimensions | 1150х600 mm | |

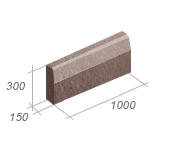

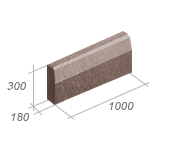

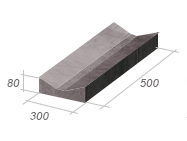

| Curb stone 1000×300×150 mm | 70 pcs./hour | Moulding cycle | 30–50 sec. | |

| Dimensions of the line: | Electric power consumption: | |||

| Length | 7400 mm | Voltage | 380 V | |

| Width | 8400 mm | Frequency | 50 HZ | |

| Height | 3000 mm | Total capacity | 33,0 kW | |

| Weight | 7,5 tonn | Operating personnel | 3-5 persons* |

* – data depend on the level of the organization of production and a way of mechanization of auxiliary works

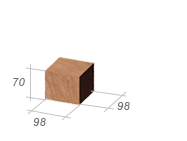

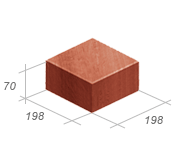

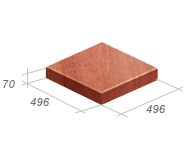

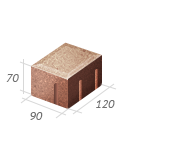

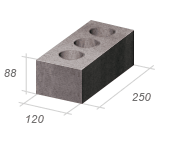

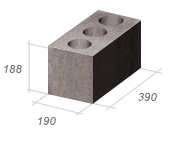

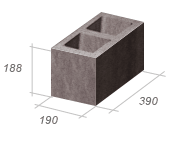

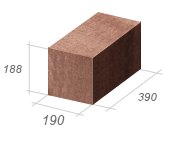

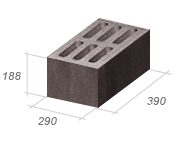

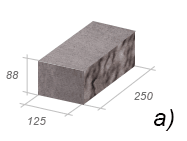

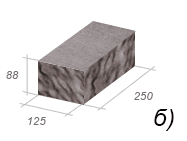

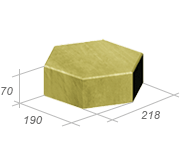

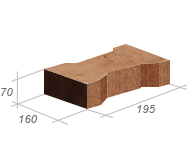

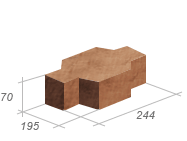

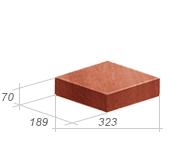

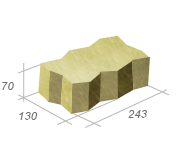

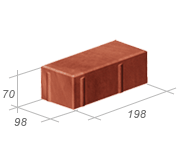

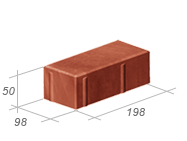

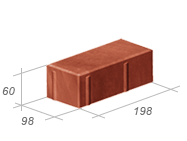

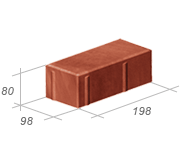

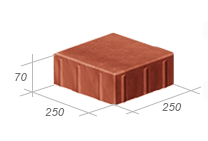

Types of products

.png)