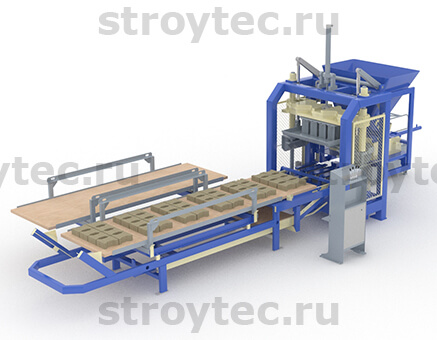

Vibrating press «Rifey-Udar»

from 2 531 000 RUB

Output per shift |

2720*pcs.

224*m2

575*pcs.

* Upon condition of continuous work of a vibrating press within 8 hours.

Equipment meets the requirements of Technical Regulation of the Customs Union

Declaration identification number

TC № RU Д-RU.АЛ16.В.29091

Date of declaration: 24.01.2014

Content:

- Vibrating press

- Component batcher

- Concrete mixer

- Control panel

- Pallet supplying system

- Rack with pallets

- Pump unit

- Conveyor

- Punch-matrix

Description

«Rifey-Udar» is an excellent ratio of the price, productivity and quality.

The name a complex («udar» means «strike») kept a trademark of the vibrocompressing complexes of the «Rifey» series and directly displays features of strike vibration system on the made concrete products.

Advantages of the vibrating press «Rifey-Udar»:

- the polyharmonic vibration system of shock type and inertial swamp weight of a punch is applied. It, in turn, allows to expand a range of application of various fractions of fillers, at production of moist rigid concrete mixes;

- contracts with the European suppliers of the most high-quality hydraulics are signed. It finally will affect reliability and durability of a vibrating press;

- a system of replacement «punch matrix» became more simply and quicker, time of replacement doesn’t exceed 40 minutes;

- it was significantly reduced a cycle of formation of-35-40 seconds.

The advanced design allows to make products from higher-quality concrete, in difference from machine of previous generation of «Rifey-Universal». All necessary units allowing to organize autonomous manufacturing of building products are its part: vibrating press, mixer, store, electricity box, batcher, mix loader, oil-pumping station. Thus, this line represents an optimum choice of machine for manufacturing of building products by method of moist vibrocompressing on a ratio the price — quality/productivity.

The line is intended for operating conditions in the territory of Russia and the CIS countries, including areas with insufficiently developed infrastructure of the building industry.the polyharmonic vibration system of shock type and inertial swamp weight of a punch is applied. It, in turn, allows to expand a range of application of various fractions of fillers, at production of moist rigid concrete mixes;

contracts with the European suppliers of the most high-quality hydraulics are signed. It finally will affect reliability and durability of a vibrating press.

a system of replacement «punch matrix» became more simply and quicker, time of replacement doesn’t exceed 40 minutes;

it was significantly reduced a cycle of formation of-35-40 seconds.

Completing variants

Vibrating press «Rifey-Udar»

Output per shift

2720*pcs.

224*m2

575*pcs.

2 531 000 RUB.

* Upon condition of continuous work of a vibrating press within 8 hours.

Technical Details:

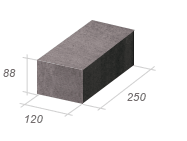

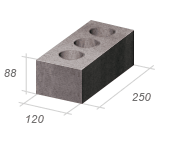

| Formed products area, mm | 800 × 400 |

| Formed products height, mm | 50-230 |

| Total capacity, kW | 16,5 |

| Dimensions of the line (L×W×H), mm | 6670 × 1245 × 2600 |

| Weight, tonn | 2,8 |

Complex «Rifey-Udar-5,0-350»

Output per shift

2720*pcs.

224*m2

575*pcs.

3 404 000 RUB.

* Upon condition of continuous work of a vibrating press within 8 hours.

Technical Details:

| Formed products area, mm | 790 × 390 |

| Formed products height, mm | 50-230 |

| Moulding pallet dimensions, mm | 900 × 450 |

| Total capacity, kW | 22 |

| Dimensions of the line (L×W×H), mm | 6600 × 4800 × 2800 |

| Weight, tonn | 4,4 |

Complex «Rifey-Udar-5,0-350-Auto»

Output per shift

2720*pcs.

224*m2

575*pcs.

4 117 000 RUB.

* Upon condition of continuous work of a vibrating press within 8 hours.

Technical Details:

| Formed products area, mm | 790 × 390 |

| Formed products height, mm | 50-230 |

| Moulding pallet dimensions, mm | 900 × 450 |

| Total capacity, kW | 22 |

| Dimensions of the line (L×W×H), mm | 6600 × 4800 × 2800 |

| Weight, tonn | 4,4 |

Complex «Rifey-Udar-5,0-550»

Output per shift

2720*pcs.

224*m2

575*pcs.

3 482 000 RUB.

* Upon condition of continuous work of a vibrating press within 8 hours.

Technical Details:

| Formed products area, mm | 790 × 390 |

| Formed products height, mm | 50-230 |

| Moulding pallet dimensions, mm | 900 × 450 |

| Total capacity, kW | 29,5 |

| Dimensions of the line (L×W×H), mm | 6600 × 4800 × 2800 |

| Weight, tonn | 4,8 |

Characteristics

Performance comparison of the «Udar» machine-types

| Completing variations | «Rifey-Udar» | «Rifey-Udar-5,0-350» | «Rifey-Udar-5,0-550» | «Rifey-Udar-5,0-350-Automatic» | «Rifey-Udar-5,0-550-Automatic» |

|---|---|---|---|---|---|

| Concrete mixer | — | SG-350 | SG-550 | SG-350 | SG-550 |

| Loading volume of concrete mixer | — | 350 liters | 550 liters | 350 liters | 550 liters |

| Spacing of agitator shaft | — | horizontal | horizontal | horizontal | horizontal |

| Component batcher | — | volumetric | weighing | volumetric | weighing |

| Productivity: | |||||

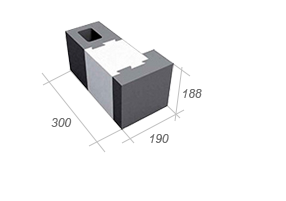

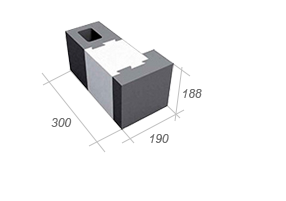

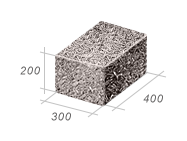

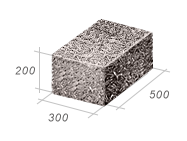

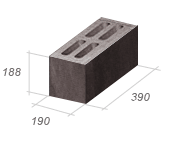

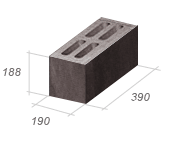

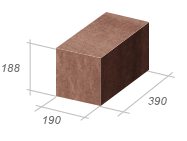

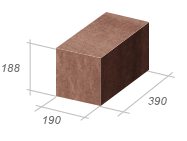

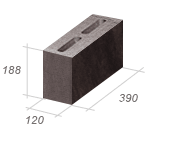

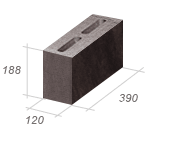

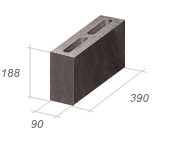

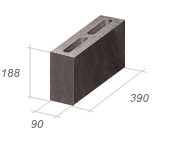

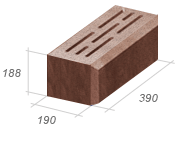

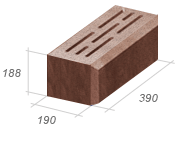

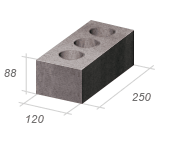

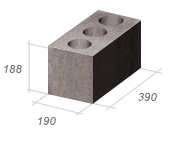

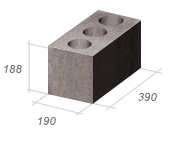

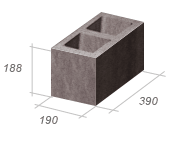

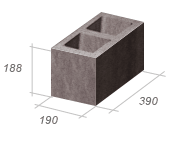

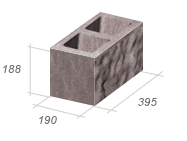

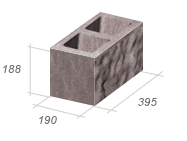

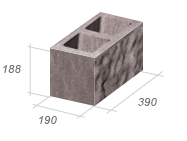

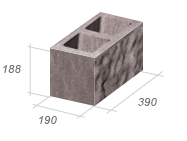

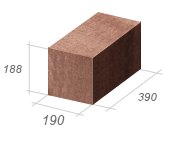

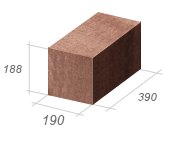

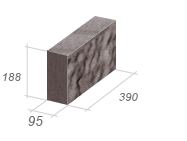

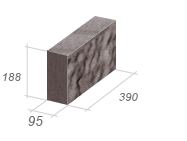

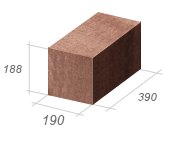

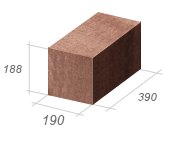

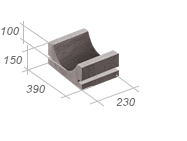

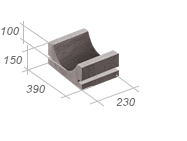

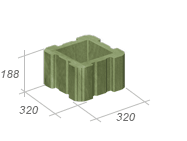

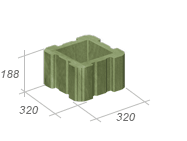

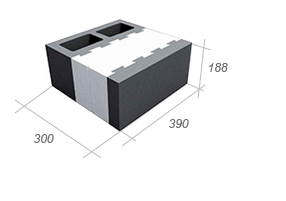

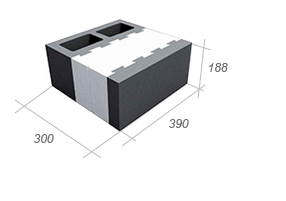

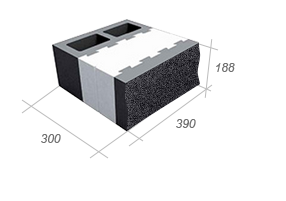

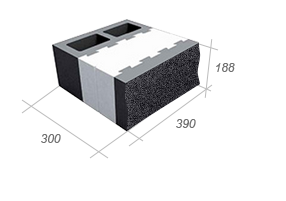

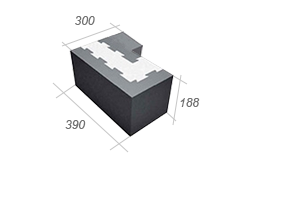

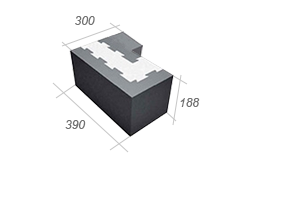

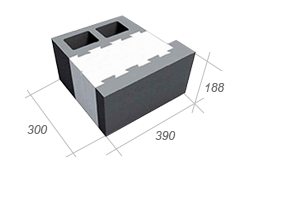

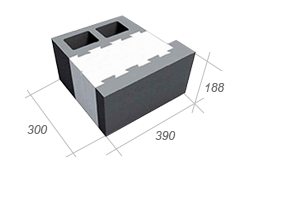

| Hollow stone 390×190×188 mm | 340 pcs./h | 340 pcs./h | 340 pcs./h | 340 pcs./h | 340 pcs./h |

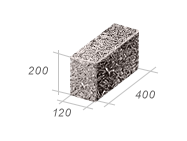

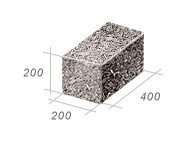

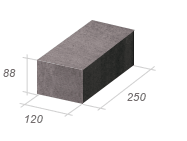

| Paving slab 200×100 mm | 28 sq. m/h | 28 sq. m/h | 28 sq. m/h | 28 sq. m/h | 28 sq. m/h |

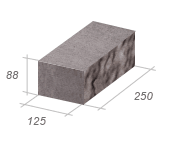

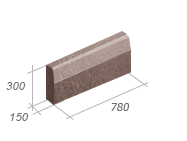

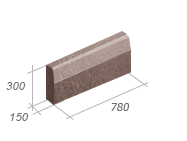

| Curb stone 780×300×150 mm | 72 pcs./h | 72 pcs./h | 72 pcs./h | 72 pcs./h | 72 pcs./h |

| Dimensions of the line: | |||||

| Length | 6600 mm | 6600 mm | 6600 mm | 6600 mm | 6600 mm |

| Width | 4800 mm | 4800 mm | 4800 mm | 4800 mm | 4800 mm |

| Height | 2800 mm | 2800 mm | 2800 mm | 2800 mm | 2800 mm |

| Weight | 2,83 tonn | 4,4 tonn | 4,8 tonn | 4,4 tonn | 4,8 tonn |

| Зона формируемых изделий | 790×390 мм | 790×390 мм | 790×390 мм | 790×390 мм | 790×390 мм |

| Formed products area | 50-230 mm | 50-230 mm | 50-230 mm | 50-230 mm | 50-230 mm |

| Formed products height | 900×450 mm | 900×450 mm | 900×450 mm | 900×450 mm | 900×450 mm |

| Moulding cycle | 30-50 с | 30-50 с | 30-50 с | 30-50 с | 30-50 с |

| Electric power consumption: | |||||

| Voltage | 380 V | 380 V | 380 V | 380 V | 380 V |

| Frequency | 50 Hz | 50 Hz | 50 Hz | 50 Hz | 50 Hz |

| Total capacity | 16,5 kW | 22 kW | 29,5 kW | 22 kW | 29,5 kW |

| Персонал | 1 persons | 3-4 persons | 3-4 persons | 2-3 persons | 2-3 persons |

X X X - different characteristics

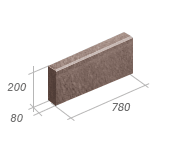

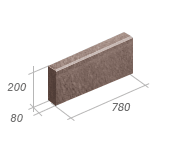

Types of products

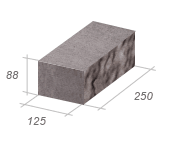

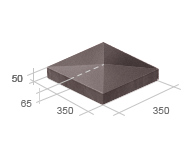

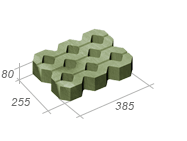

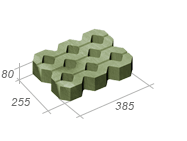

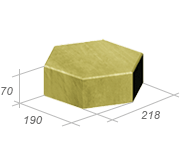

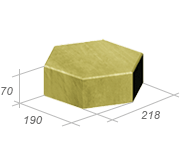

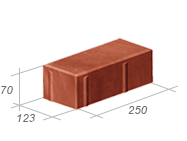

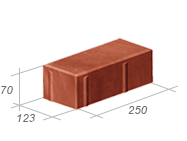

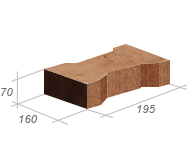

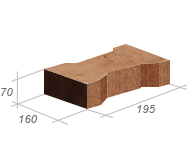

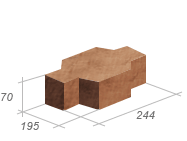

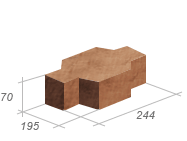

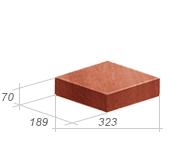

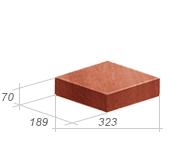

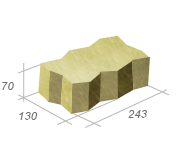

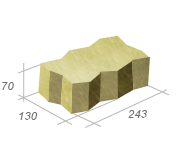

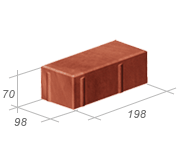

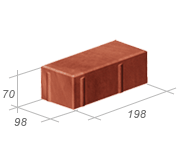

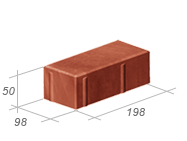

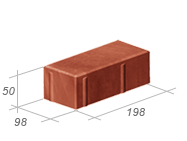

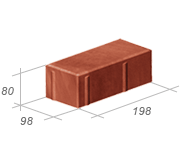

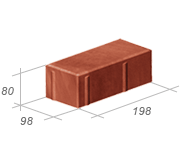

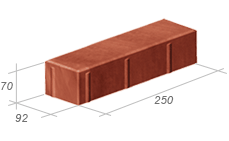

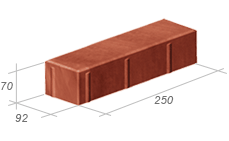

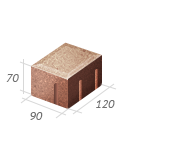

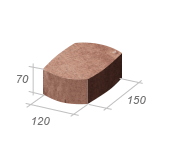

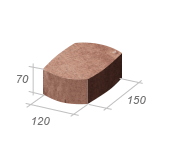

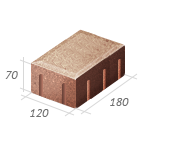

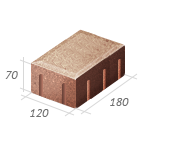

101.6

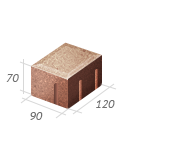

102.6

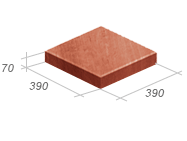

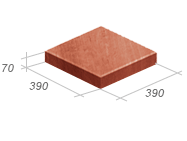

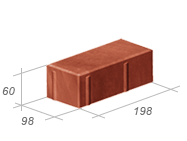

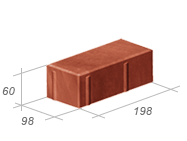

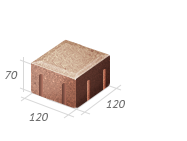

108.6

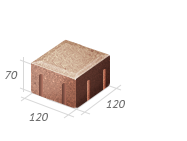

109.6

110.6

130.6

145.6

151.6

158.6

171.6

172.6

197.6

197.6

197.6

112.6

439.6

605.6

622.6

401.6

402.6

403.6

405.6

407.6

408.6

419.6

430.6

430.6А

430.6Б

430.6В

449.6

459.6

460.6

491.6Б

491.6В

491.6Г

491.6Д

614.6

616.6

701.6

701.6Б

702.6

703.6

704.6