Vibrating presses «Kondor»

from 538 000 RUB

Output per shift |

800*pcs.

65*m2

2400*pcs.

* Upon condition of continuous work of a vibrating press within 8 hours.

Equipment meets the requirements of Technical Regulation of the Customs Union

Declaration identification number

TC № RU Д-RU.АЛ16.В.29091

Date of declaration: 24.01.2014

Content:

- Vibrating press

- Punch-matrix

- Batch

- Conveyor

- Concrete mixer

- Support stand

- Control panel

- Pump unit

- Rack

- Pallets

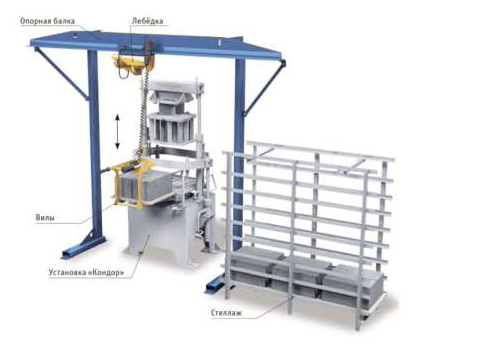

Description

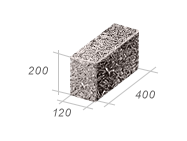

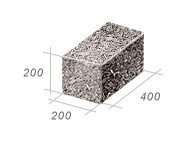

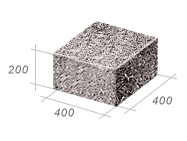

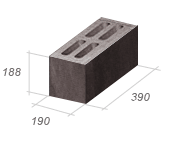

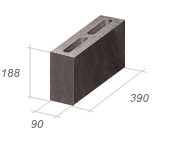

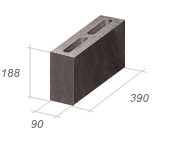

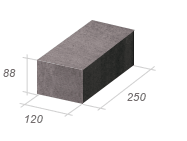

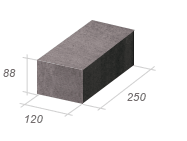

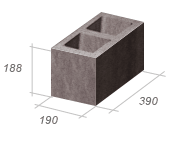

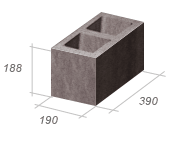

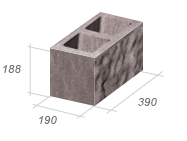

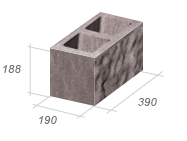

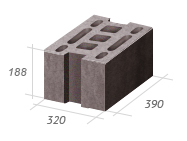

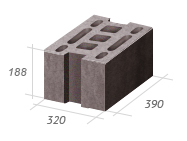

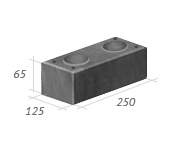

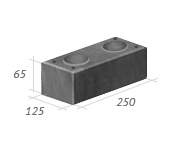

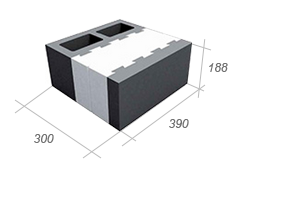

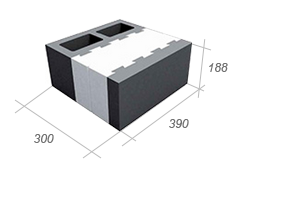

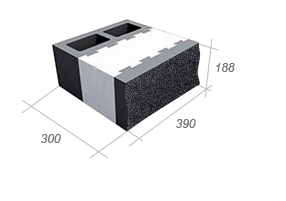

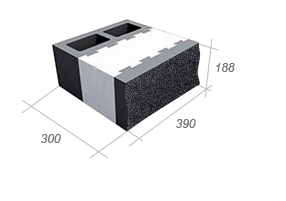

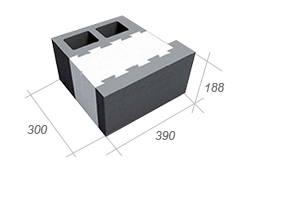

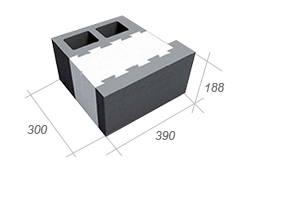

Vibrating press the CONDOR 1 is the high-performance processing unit intended for production of wall stones and paving slabs from rigid concrete mix by a vibrocompressing method in the conditions of private construction and commercial production in small business. The set of the replaceable form-building equipment allows to make the following products : wall stones (course, corner, partition, facing, solid and hollow), paving slabs of different configuration and sizes, curbstones, park amenities.

Advantages of the processing units of "Kondor" series |

|

|

|

Completing variants

Processing unit for producing of building products "Kondor-1"

Output per shift

800*pcs.

65*m2

2400*pcs.

245 000 RUB.

* Upon condition of continuous work of a vibrating press within 8 hours.

Content:

- Vibrating press

- Punch-matrix

- Control panel

- Pump unit

- Pallets, 5 pcs.

Technical Details:

| Voltage | 380 V. |

| Capacity | 4,4 kW. |

| Weight | 710 kg. |

| LхWхH | 1200х1500х1700 mm. |

Processing unit for producing of building products "Kondor-1-40"

Output per shift

800*pcs.

65*m2

1650*pcs.

320 000 RUB.

* Upon condition of continuous work of a vibrating press within 8 hours.

Content:

- Vibrating press

- Punch-matrix

- Concrete mixer, V=40 л.

- Support stand

- Control panel

- Pump unit

- Rack

- Pallets, 5 pcs.

Technical Details:

| Voltage | 380 V. |

| Capacity | 8,4 kW. |

| Weight | 930 kg. |

| LхWхH | 1700х1500х1700 mm. |

Processing unit for producing of building products "Kondor-1-40/220"

Output per shift

550*pcs.

45*m2

1650*pcs.

345 000 RUB.

* Upon condition of continuous work of a vibrating press within 8 hours.

Content:

- Vibrating press

- Punch-matrix

- Concrete mixer, V=40 l.

- Support stand

- Control panel

- Pump unit

- Rack

- Pallet, 5 pcs.

Technical Details:

| Capacity | 8,4 kW. |

| Weight | 930 kg. |

| LхWхH | 1700х1500х1700 mm. |

| Voltage | 220 V. |

Processing unit for producing of building products "Kondor-1-150-TB"

Output per shift

800*pcs.

65*m2

2400*pcs.

490 000 RUB.

* Upon condition of continuous work of a vibrating press within 8 hours.

Content:

- Vibrating press

- Punch-matrix

- Single-batcher

- Support stand

- Concrete mixer, V=150 l.

- Conveyor

- Control panel

- Pump unit

- Rack

- Pallet, 5 pcs.

Technical Details:

| Voltage | 380 V. |

| Capacity | 13 kW. |

| Weight | 1215 kg. |

| LхWхH | 5000х1500х2800 mm. |

Processing unit for producing of building products "Kondor-1-150-TSP"

Output per shift

800*pcs.

65*m2

2400*pcs.

590 000 RUB.

* Upon condition of continuous work of a vibrating press within 8 hours.

Content:

- Vibrating press

- Concrete mixer, V=150 l.

- Conveyor

- Punch-matrix

- Pallet, 5 pcs.

- Rack

- Pallet feed module 9

- Blending module

Technical Details:

| Voltage | 380 V. |

| Capacity | 13 kW. |

| Weight | 1215 kg. |

| LхWхH | 5000х1500х2800 mm. |

Processing unit for producing of building products "Kondor-1-350-TB"

Output per shift

800*pcs.

65*m2

2400*pcs.

585 000 RUB.

* Upon condition of continuous work of a vibrating press within 8 hours.

Content:

- Vibrating press

- Punch-matrix

- Concrete mixer, V=350 l.

- Conveyor

- Double-batcher

- Control panel

- Pump unit

- Rack

- Pallet, 5 pcs.

Technical Details:

| Voltage | 380 V. |

| Capacity | 13 kW. |

| Weight | 2 160 kg. |

| LхWхH | 5800х2100х2800 mm. |

Processing unit for producing of building products "Kondor-1-350-TSP"

Output per shift

800*pcs.

65*m2

2400*pcs.

685 000 RUB.

* Upon condition of continuous work of a vibrating press within 8 hours.

Content:

- Vibrating press

- Concrete mixer, V=350 l

- Conveyor

- Punch-matrix

- Pallet, 5 pcs.

- Rack

- Pallet feed module 9

- Blending module

Technical Details:

| Voltage | 380 V. |

| Capacity | 13 kW. |

| Weight | 2 160 kg. |

| LхWхH | 5800х2100х2800 mm. |

Processing unit for producing of building products «Bikondor 150-TB»

Output per shift

1600*pcs.

130*m2

4800*pcs.

750 000 RUB.

* Upon condition of continuous work of a vibrating press within 8 hours.

Content:

- Vibrating press, 2 pcs.

- Punch-matrix, 2 pcs.

- Double-batcher

- Concrete mixer, V=150 l.

- Conveyor

- Control panel, 2 pcs.

- Pump unit, 2 pcs.

- Rack, 2 pcs.

- Pallets, 10 pcs.

Technical Details:

| Voltage | 380 V. |

| Capacity | 17,4 kW. |

| Weight | 2000 kg. |

| LхWхH | 4700х3200х2800 mm. |

Processing unit for producing of building products «Bikondor 350-TB»

Output per shift

1600*pcs.

130*m2

4800*pcs.

845 000 RUB.

* Upon condition of continuous work of a vibrating press within 8 hours.

Content:

- Vibrating press, 2 pcs.

- Punch-matrix, 2 pcs.

- Concrete mixer, V=350 l.

- Double-batcher

- Conveyor

- Control panel, 2 pcs.

- Pump unit, 2 pcs.

- Rack, 2 pcs.

- Pallets, 10 pcs.

Technical Details:

| Voltage | 380 V. |

| Capacity | 17,4 kW. |

| Weight | 2910 kg. |

| LхWхH | 5300х3200х2800 mm. |

Processing unit for producing of building products «Trikondor 350-TB»

Output per shift

2400*pcs.

195*m2

7200*pcs.

1 070 000 RUB.

* Upon condition of continuous work of a vibrating press within 8 hours.

Content:

- Vibrating press, 3 pcs.

- Punch-matrix, 3 pcs.

- Concrete mixer, V=350 l.

- Conveyor

- Triple-batcher

- Control panel, 3 pcs.

- Pump unit, 3 pcs.

- Rack, 3 pcs.

- Pallets, 15 pcs.

Technical Details:

| Voltage | 380 V. |

| Capacity | 21,9 kW. |

| Weight | 3690 kg. |

| LхWхH | 5800х3200х2800 mm. |

Additional equipment

Pallet-removal device |

Benefits |

|

1. Considerably facilitates work of the vibrating press operator. 2. Need for involvement of the additional worker for the help to the vibrating press operator disappears. 3. The device can be used for any of installations of the "Kondor" series. The electric winch 220V, 930 W. DESCRIPTIONThe pallet-removal device consists of a basic girder on which is fixed the carriage with the winch, and the pitchfork suspended on a winch cable. A winch control panel is fixed on a pitchfork. Manipulating the control panel button of the winch and a pitchfork the operator removes with little effort the pallets with the moulded products and moves it to the shelf of a rack. Filling of rack goes from the bottom upwards. After filling , the rack is taken away, and an empty rack is putted on its place.50 000 RUB.

|

Batchers on support stand |

Mixers on support stand |

|||

|

|

|

|

|

| Single-batcher | Double-batcher | Triple-batcher | Volume 40 liters | Volume 90 liters |

Floor-standing mixer with conveyor |

||

|

|

|

| Volume 350 liters | Volume 90 liters | Volume 40 liters |

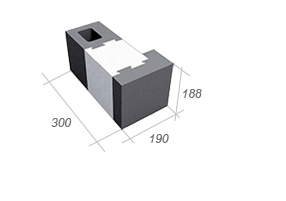

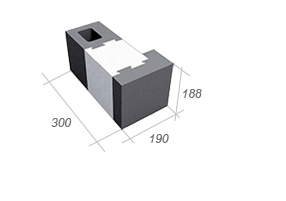

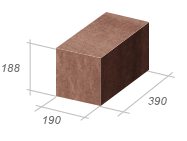

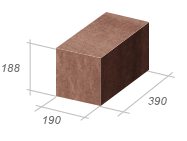

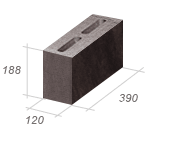

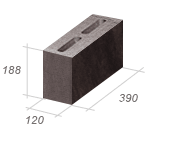

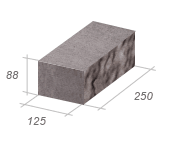

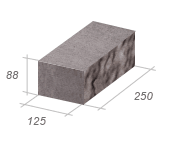

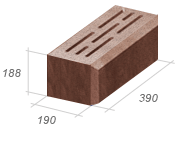

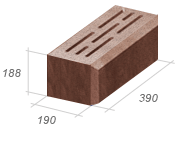

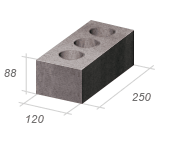

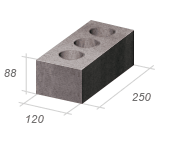

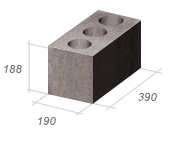

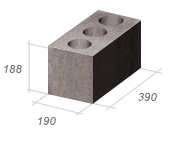

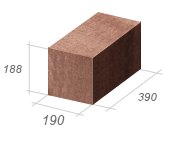

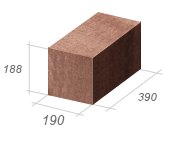

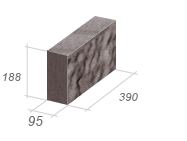

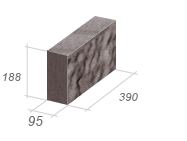

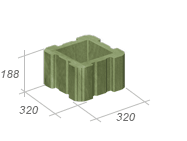

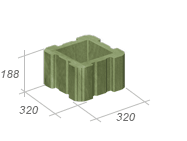

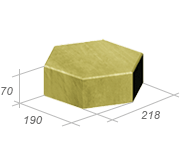

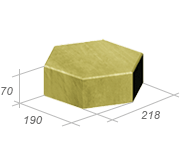

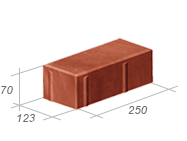

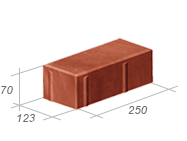

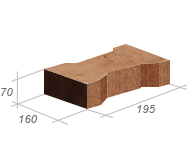

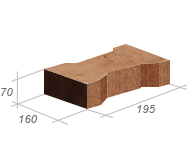

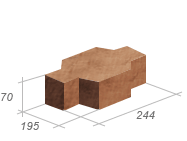

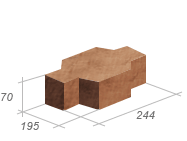

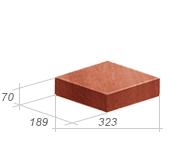

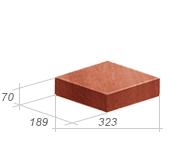

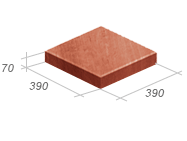

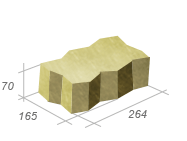

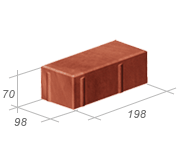

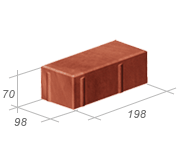

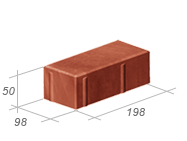

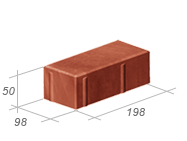

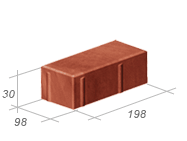

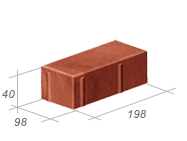

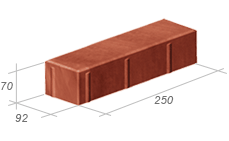

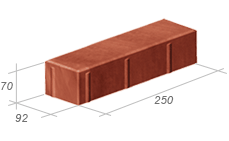

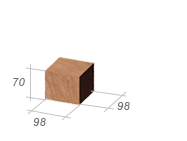

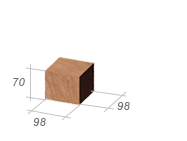

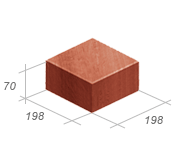

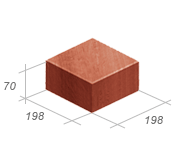

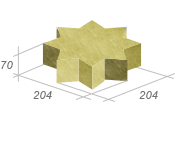

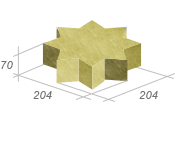

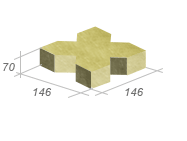

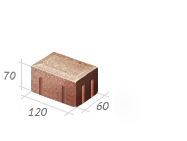

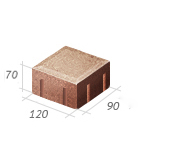

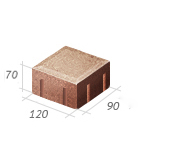

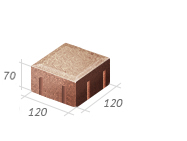

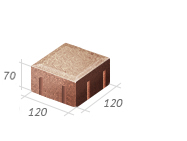

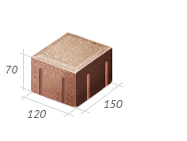

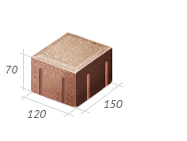

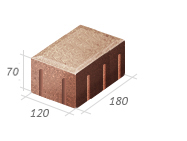

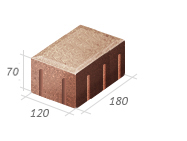

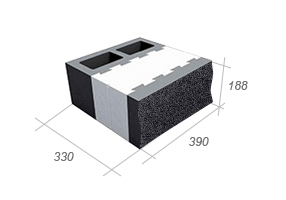

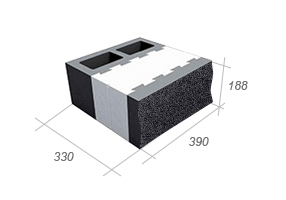

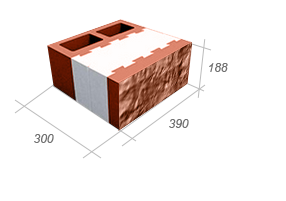

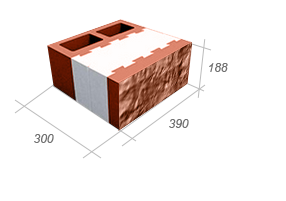

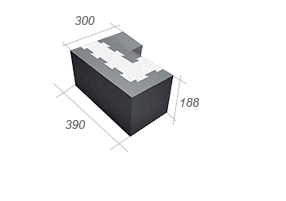

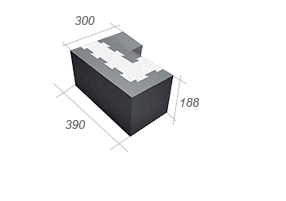

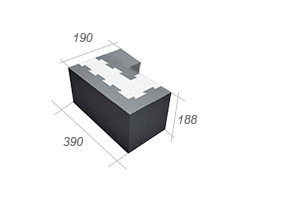

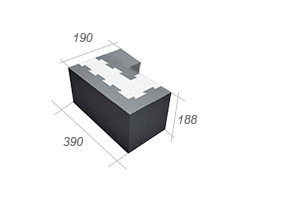

Types of products

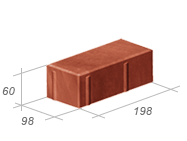

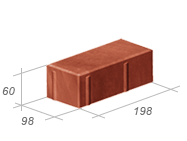

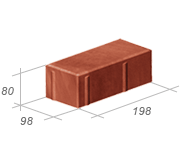

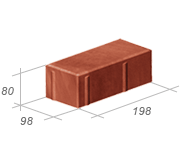

101.3

102.3

108.3

109.3

110.3

112.3

130.3

145.3

151.3

158.3

172.3

197.3

197.3

0.0

721.3

439.3

605.3

622.3

401.3

402.3

403.3

405.3

407.3

408.3

419.3

430.3

430.3А

430.3Б

430.3В

430.3Д

430.3Е

449.3

459.3

460.3

477.3А

477.3Б

491.1.3А

491.1.3Б

491.1.3В

491.2.3Г

491.2.3Д

646.3

648.3

701.3

701.3Б

701.3В

701.3Ф

702.3

702.3В

703.3

704.3