Vibrating press «Rifey-Buran-M»

Output per shift |

Equipment meets the requirements of Technical Regulation of the Customs Union

Declaration identification number

TC № RU Д-RU.АЛ16.В.29091

Date of declaration: 24.01.2014

Content:

- Concrete mixer

- Conveyor

- Vibrating press

- Palette

- Control panel

- Pump unit

- Punch-matrix

Description

«Rifey-Buran» for sale. «Rifey-Buran» – the fastest and technologically perfect line «Rifey».

Purpose of the "Rifey-Buran" line

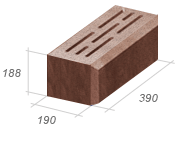

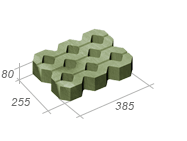

| The high-performance compact mechanized "Rifey-Buran" line for production of wall materials and park amenities by method of moist vibrocompressing. "Rifey-Buran" is developed especially for operation in Russia and the CIS countries, including the regions with undeveloped infrastructure of building industry. It produces a full set of materials for construction of house walls and modern amenities. Wall, shuttering and facing stones, curb stones, trays, paving slabs for slope protection, stones for a fence, 20 types of paving slabs, ladder tread. The unique and economic technology of concreting of columns and crossbars without wooden timbering is created. Architectural expressiveness due to creation of reliefs on walls and corners of the house is reached. It is no need in face stucco. By fitting of the line with the module of automatic control, productivity of the line increases to 20%, the line can be also completed with the module for production of a two-layer slab. |

Completing variants

Vibrating press «Rifey-Buran-M»

Output per shift

Technical Details:

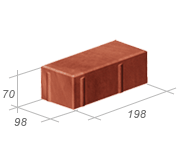

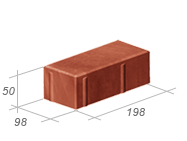

| Formed products area, mm | 1000×500 |

| Formed products height, mm | 50-240 |

| Total capacity, kW | 19,0 |

| Dimensions of the line (LxWxH), mm | 7390 × 2000 × 2800 |

| Weight, tonn | 5,8 |

Complex «Rifey-Buran-M»

Output per shift

Technical Details:

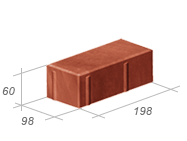

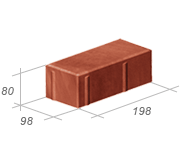

| Formed products area, mm | 500×1000 |

| Formed products height, mm | 50–250 |

| Total capacity, kW | 36,2 |

| Dimensions of the line (LxWxH), mm | 7400 × 9500 × 3450 |

| Weight, tonn | 9,3 |

Characteristics

Stone molding, as well as on all other lines of the "Rifey" series, is made on pallets, however on the "Rifey-Buran" line it can be used pallets from 8 to 40 mm thick, thus the vibrating press doesn't demand any additional change-over. It is necessary to notice that quality of the manufactured products depends on quality of pallets and developers recommend to use the plywood or wooden pallets 40 mm thick which are pulled together with metal studs.

| Productivity*: | Formed products area | 500×1000 mm | ||

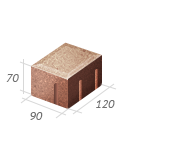

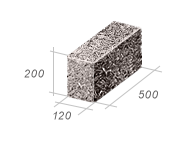

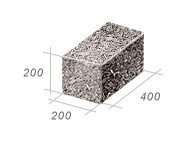

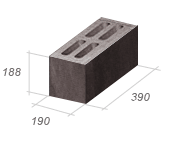

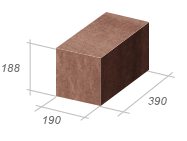

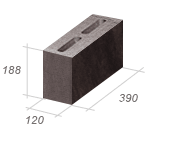

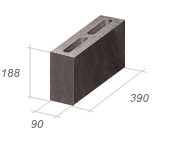

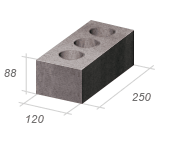

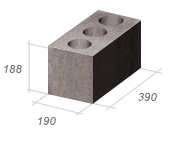

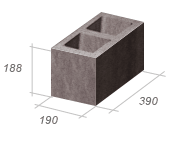

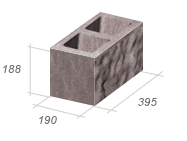

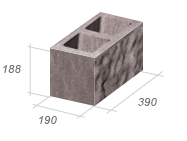

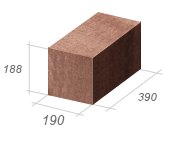

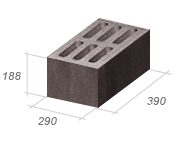

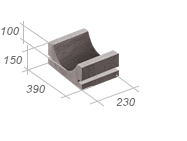

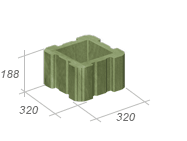

| Hollowstone 390×190×188 mm | 500 pcs./hour | Formed products height | 50–250 mm | |

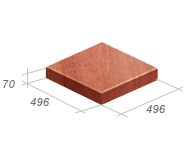

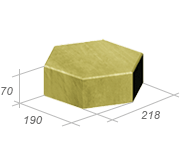

| Paving slab 200×100 mm sq. m | 56 sq.m/hour | Moulding pallet dimensions | 1150×600 mm | |

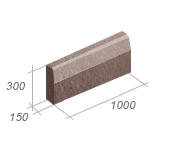

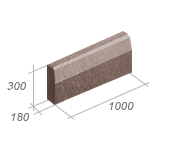

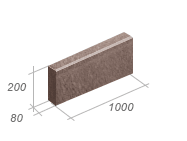

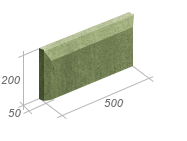

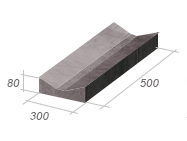

| Curb stone 1000×300×150 mm | 80 pcs./hour | Moulding cycle | 30–50 sec. | |

| Dimensions of the line: | Electric power consumption: | |||

| Length | 7400 mm | Voltage | 380 W | |

| width | 9500 mm | Frequency | 50 Hz | |

| Height | 3450 mm | Total capacity | 36,2 kW | |

| Weight | 9,3 tonne | Operating personnel | 3–5 persons* |

* — data depend on the level of the organization of production and a way of mechanization of auxiliary works

Other distinctive feature is simplicity and speed of replacement of form-building equipment. It is enough to turn off 10 bolts and the load-lifting mechanism to take a matrix and a punch through the top, free zone of a vibrating press. If the replaced matrix has other height, it is necessary, by means of jacks to lift or lower the loading module. This, rather simple operation, doesn't take a lot of time. Other reorganizations it isn't required.

One more feature of the Rifey-Buran line is that when unloading ready stones pallets from a rack aren't removed (only products are removed), thus during all cycle the man’s hand doesn't touch pallets.

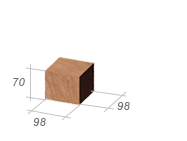

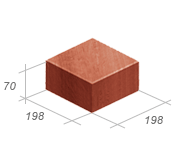

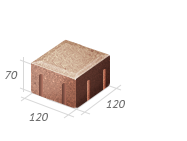

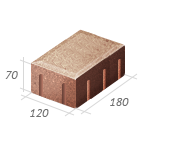

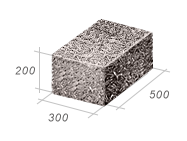

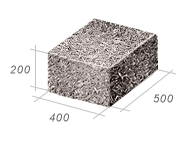

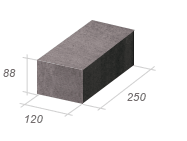

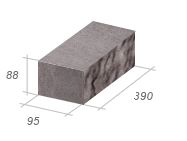

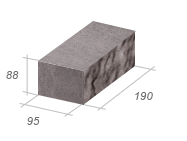

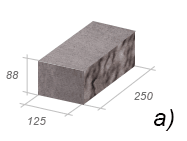

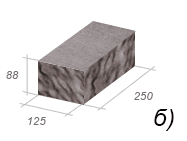

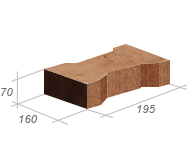

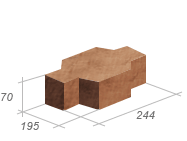

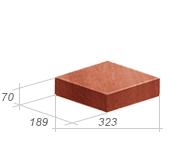

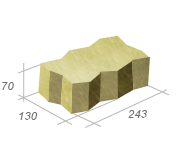

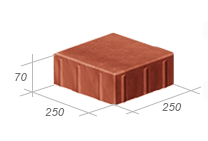

500×1000 mmTypes of products

.png)